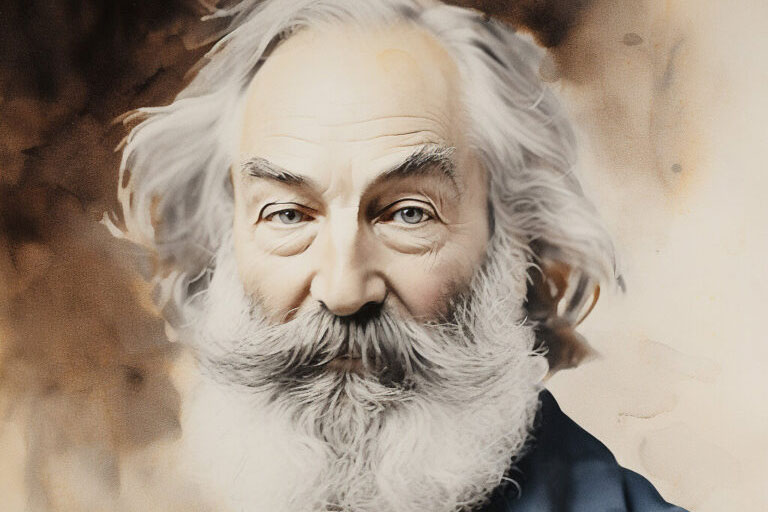

Eric Roy, technical coordinator for the Saint Michael’s College MakerSpace in Dion Family Student Center, said that just before the Spring Break commenced, a flurry of activity launched in the “Maker Community” nationally to leverage Urban Manufacturing and Rapid Prototyping tools to respond to the rapid increase in need for Personal Protective Equipment (PPE) and other medical tools.

Eric Roy of Saint Michael’s College works to make essential personal protective equipment (PPE) at Burlington’s Generator makerspace recently.

Roy said Vermont was one of many states that found increased challenges with the traditional supply chains and access to the resources that officials anticipated needing to respond to the Pandemic. Responding to that challenge, Generator, the Burlington Community Makerspace, worked with an array of partners and community leaders “to spin up a cohort of local level producers to make Face Shields and Intubation Boxes for University of Vermont Medical Center,” he said.

For Roy, that presented an opportunity to utilize the Saint Michael’s MOVE program’s volunteer program offered to Employees through the Wellbeing Collaborative. Mobilization of Volunteer Efforts (MOVE) offers up to 40 hours of paid volunteer time annually to qualified faculty and staff for volunteering locally or through one of the many annual service trips. This program was developed to further the College’s goals of investing in the community and bolstering the Saint Michael’s tradition of service.

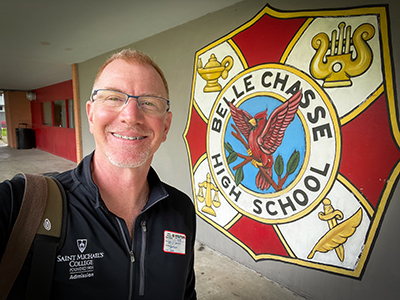

Through that MOVE opportunity through the College, Roy said he has been aiding Generator to temporarily increase their 3D printing fleet from two to eleven machines. These Fused Deposition Modeling (FDM) printers are being run around the clock to produce the headbands for Face Shields worn over other PPE.

A University of Vermont Medical Center doctor wears personal protective equipment fabricated at Burlington’s Generator Makerspace by Eric Roy of Saint Michael’s College and his colleagues.

“We are running the printers at faster than typical speeds… [and] keeping them at full throughput has required quite a bit of TLC,” he said. Roy is one of several technicians servicing the printers, and the full production team has been working at a feverish pace to fulfill the additional orders placed by the state.

As of April 28, 2020, Roy said, “We had reached 3,383 fully assembled face shields. It’s been amazing to see an educational and co-working space shift its operations in such a short turnaround to address community issues like this.”

Typically, he said, Generator, a nonprofit, is focused on serving members, running hands-on technology and art classes, and organizing STEM educational programs for youth. “Pivoting to become a pop-up fabrication facility has taken an incredible amount of effort, communication, and follow through,” Roy said. “The work this team and its partners are doing has been significant in helping Vermont weather this storm.”

For more information about this endeavor and Generator’s partners, please visit the following links:

https://www.vpr.org/post/vermont-manufacturers-help-supply-ppe#stream/0

https://www.vpr.org/post/vermont-makerspace-hopes-help-local-hospital-3d-printing-ppe#stream/0

For all press inquiries contact Elizabeth Murray, Associate Director of Communications at Saint Michael's College.